- Home

- Companies

- Begg Cousland Envirotec Limited

- Applications

- Filter solution for NaOH stream duty ...

Filter solution for NaOH stream duty sector - Chemical & Pharmaceuticals - Fine Chemicals

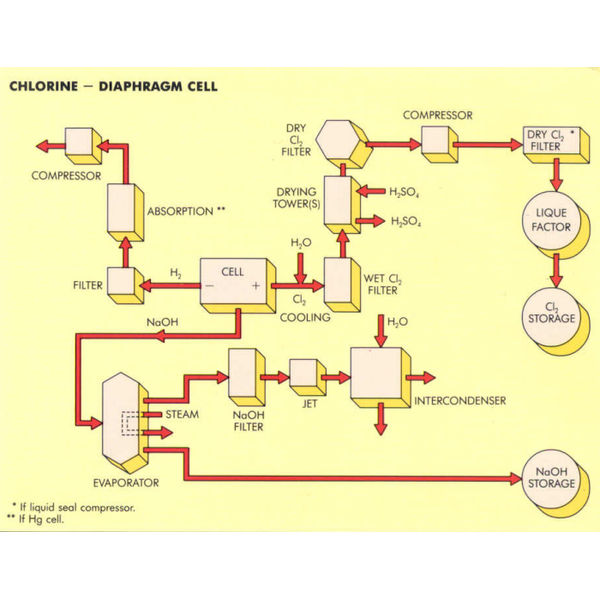

Process Information: Electrolysis of brines with chlorine production at the anode and hydrogen together with sodium or potassium hydroxide at the cathode.

Types of cells: diaphragm

- Diaphragm membrane

- mercury

Diaphragm Cell

The diaphragm cells contain a porous asbestos diaphragm to separate the anode from the cathode. This allows ions to pass through by electrical migration but reduces diffusion of products.

Anodes are graphite or Titanium (DSA).

Cathodes are made from steel wire.

Overall reaction:

NaCl + H2O – NaOH + 1/2 H2 + 1/2 Cl2

If OH* reach the anode hypochlorites are formed with subsequent loss of chlorine.

The following occurs:

2OH* – H2O + 1/2 O2 + 2E

The oxygen will attack the graphite and chlorinated HC are entrained in chlorine gas.

Mercury Cell

In a mercury cell, brine is partly decomposed in the electrolyzer between a graphite anode and a moving mercury cathode forming chlorine gas at the anode and sodium amalgam (NaHg) at the cathode.

The amalgam flows to the decomposer box where it becomes the anode to a short circuited iron or graphite cathode in an electrolyte of sodium hydroxide solution.

Purified water is fed to the decomposer; hydrogen is formed and NaOH concentration increases. Hg is formed and recycled to the electrolyzer.

- Reactions:

electrolyzer 2Na Cl + Hg – Cl2 + 2Na(Hg) - decomposer 2Na(Hg) + 2H2O – 2NaOH + H2 + Hg

NaOH Stream

Often NaOH is concentrated from 50% or lower strength up to 70%. This operation is carried in a high vacuum (120 mmHg ABS) concentrator. Vacuum is generated by jet system with water intercoolers.

NaOH is entrained by the jet system up to 2,000 mg/Nm³.

Problems To Solve

Filters are installed before jet system to collect NaOH mists which mix with the water of intercondenser and create water pollution problem.

Design Solution

- HTP Panel filter of SS316 casing with T80.35 PTFE Teflon fibre

- Candle Filters Type F2 with SS316 structure and T80.35 PTFE Teflon fibre