- Home

- Companies

- Mantec Technical Ceramics Ltd

- Articles

- Ceramic membranes in the ...

Ceramic membranes in the pharmaceuticals industry - Case Study

GlaxoSmithKline, the pharmaceuticals giant, cut operating costs at its drugs plant in Worthing UK, by replacing polymer with Star-Sep™ Ceramic Membranes

The installation of a Star-Sep™ Ceramic Membrane system was a critical, yet proportionally low-cost component of GlaxoSmithKline’s anti-biotic drug processing system, enabling a multi-million pound investment to be recouped within just 15 months.

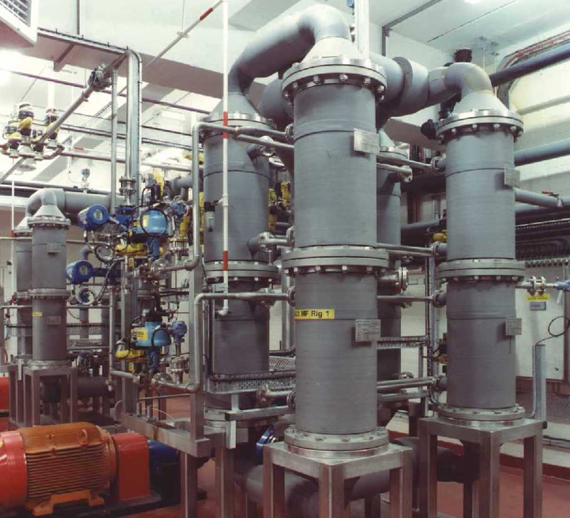

GlaxoSmithKline, the pharmaceuticals giant, cut operating costs at its drugs plant in Worthing UK, by replacing polymer with Star-Sep™ Ceramic Membranes. The filtration system supplied by Mantec Technical Ceramics comprised 4 banks of 8 housings, each housing containing 108 ceramic membranes. The total installation being 208 m2.

The principal of crossflow microfiltration is common in many processing environments and is used in anti-biotic drug production to separate residual matter from a process liquor.

Cells are grown and then mixed with a liquid formula to give the drug its essential ingredients, after which the residual cells need to be extracted. The liquor is re-circulated through porous ceramic tubular membranes, forcing the fluid filtrate through the membrane by virtue of pressure differential whilst the concentrated residual matter continues through the membrane for disposal as a waste by-product. A solvent extraction method is then used to purify the drug.

The Star-Sep™ Ceramic Membranes offered GlaxoSmithKline several economic advantages over their polymer predecessors – they require less maintenance, are easily cleaned and have a greater life expectancy. But the most significant benefit is in energy savings. Crossflow microfiltration is necessarily energy-intensive. In order to achieve the required crossflow velocity, a high crossflow volume is required and hence the need for high-powered pumping system that consume a great deal of energy. Mantec’s unique membranes, featuring star-shaped flow-channels, drastically reduce the energy required to re-circulate the liquor.

The ceramic membranes’ multiple flowpaths are narrow, maximising the surface area and minimising the retentive cross-sectional area. The irregular shape also induces turbulence, the net effect being to reduce the crossflow volume by 50%.

This has a direct impact on pump energy input, reducing it by a similar amount. The ceramic media offers superior filtration performance, with double the flux of polymer units, reducing energy input by 50% and bringing a total reduction of 75%. In addition to substantial savings on processing costs, savings can also be made on equipment infrastructure costs, particularly by using smaller pumps and valves. The ceramic membrane module was a critical, yet proportionally low-cost component of GlaxoSmithKline’s new anti-biotic drug processing system, enabling a multi-million pound investment to be recouped within just 15 months.