Refine by

Oem&Nbsp;Medical Device Articles & Analysis

26 articles found

It is not surprising then that some medical device original equipment manufacturers (OEMS) encounter difficulties right from the start. Insufficient tolerance analysis can affect the entire project. ...

During a customer visit campaign, I had the opportunity to speak with a Machinery OEM who explained to me that he was satisfied with our actual range of metal enclosures due to its level of robustness. ...

Particularly with the medical device market, OEMs must provide specialized facilities for manufacturing such products, and have on-site medical labs for all stages of production, from concept to design to manufacturing. Labs give engineers the opportunity to validate and verify new products, plus allow for modification or change in design as needed. How Can an ...

Manufacturers and medical device OEMs are producing devices with more efficiency, accuracy, reliability and capability than ever — all while achieving higher-quality, less expensive tools for healthcare providers to use. ...

Disinfection: Manual (open RABS) Define the right disinfectant and sporicidal agent Disinfectant rotation • Disinfection technique Vaporization Support for reviewing validation documentation from OEM Cleaning techniques employing the use of a detergent. In the next blog in this series we will examine what Set up and Process Interventions on a new fill line ...

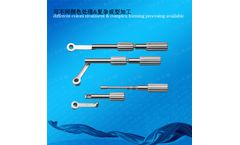

Description Application domain: Implant Material: Ultra high anti-rust & high-hardness stainless steel, titanium, titanium alloy, high anti-rust stainless steel Type: Open type, closed type LZQ is an OEM factory for all kinds of dental implant wrenches, such as, Drill Key,Parallel Pin, Wrench , Screwdriver, Tap, Lance Drill, etc. ...

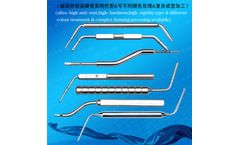

Description of soft tissue punch Application domain: for implantology Material: Ultra high anti-rust & high-hardness stainless steel, titanium, titanium alloy, high anti-rust stainless steel LZQ is an OEM factory for all kinds of dental implant trephines, such as Bone Fetcher P165, Drill Bit 096, Cutting Bur/Bone File P190, Endoscopic/Arthroscopic Shaver blade P259, ...

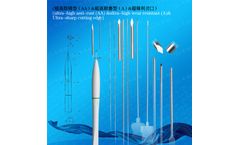

Description of sinus lift burs Application domain: dental, orthopedic surgery, maxillofacial surgery, neurosurgery Material: Ultra-high anti-rust and high-hardness stainless steel, Ultra high rust-proof and high wear-resistant stainless steel, diamond, carbide, SDC&CBNC LZQ is an OEM factory for all kinds of medical bur, such as Cutting Bur/Bone File P190, Drill Key P47, ...

Description Application domain: for arthroscopy endoscope Material: Super-high rust-resistant high-hardness stainless steel, ceramics, generally stainless steel LZQ is an OEM factory for all kinds of shaver blades, such as Endoscopic/Arthroscopic Shaver blade P259, Bone Drill Point P227, Bone Fetcher P165, Drill Bit 096, etc. ...

Description Application domain: for implantology Material: Ultra high anti-rust & high-hardness stainless steel, titanium, titanium alloy, high anti-rust stainless steel LZQ is an OEM factory for all kinds of dental implant tools, such as Depth gaugeP43, Parallel Pin P37, Drill Key P47, Wrench P53, Screwdriver P79, Tap P152, Lance Drill P172,Bone Drill Point P227, ...

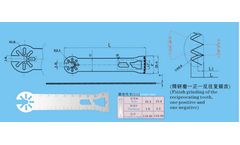

Description of DSR7 LZQ is an OEM factory for all kinds of medical tools, such as Parallel Pin P37, Drill Key P47, Wrench P53, Screwdriver P79, Tap P152, Lance Drill P172,Bone Drill Point P227, ect. ...

Description of bone tap Application domain: for Medical Material: Super-high rust-resistant high-hardness stainless steel,ceramics, generally stainless steel LZQ is an OEM factory for all kinds of dental implant tap, such as Abutment/Transfer P25,Parallel Pin P37, Wrench P53, Screwdriver P79, Tap P152, Bone Fetcher P165,Lance Drill P172, etc. ...

Description Application domain: orthopedicsMaterial: Ultra-high anti-rust high-hardness stainless steel, general rust-proof ultra-high wear-resistant stainless steel, ceramicType:Bone saws, Gums sawsLZQ is an OEM factory for all kinds of dental implant wrenches, such as Bone Saw P250, Cutting Bur/Bone File P190, Endoscopic/Arthroscopic Shaver blade P259, Bone Drill Point P227, ...

Description of 7c27mo2 LZQ is an OEM factory for all kinds of medical tools, such as Abutment/Transfer P25, Parallel Pin P37, Wrench P53, Chip Collection Drill P098, Bone Fetcher P16, ect. ...

With our own R&D department , more than 30 experienced engineers, we have the ability to do ODM & OEM project. Welcome all kinds inquiries for hearing aids & hearing amplifier. 2013 Cooperated with Indian No. 2 medical company Dr. ...

What is 19C27? Description LZQ is an OEM factory for all kinds of medical tools, such as Profile Drill P144, Dental Milling Bur/ Zirconia Bur P245, High Precision Fittings P76, Abutment/Transfer P25, ect. ...

With our own R&D department , more than 30 experienced engineers, we have the ability to do ODM & OEM project. Welcome all kinds inquiries for hearing aids & hearing amplifier. 10 years R&DExtensive ExperienceIn 2008, we began R&D and manufacturing hearing aid. 10 years we have been consistently dedicated in producing advanced hearing technologies. 100+ ...

Size:Customized as per request Material: bamboo, sugarcane byproduct, bagasse Type: molded pulp tray/box Color: White or other color Advantage: automatic machine made, High-Quality, 100% biodegradable, allmeets export standard Process Type: Pulp Molding Usage:lining /insert/packaging box Use: cosmetics packaging Package: with PE bag pack in corrugated master shipping carton box and standard ...

Specification of JH-238 Pocket Body Worn Hearing Aid Hearing Amplifier Product name Rechargeable ITE hearing aids sound amplifier Title of commodity/item number Rechargeable hearing aid/JH335 Color Beige/optional colors Frequency range 200Hz-7000Hz Total harmonic wave distortion 500HZ≤2.7%, 70dB 800HZ≤0.5%, 70dB 1600HZ≤0.1%, 65dB OSPL90 Max at 1500Hz/136.8dB HFA/AVG/124.9dB FOG50 Max ...

Moreover, as no release agent is required during the manufacturing process, the resultant porous plastic materials produced have a level of purity that will be readily compatible with even the most challenging healthcare applications." He added "Early feedback from OEM customers receiving Vyon porous plastic components manufactured using the automated system has been excellent ...