- Home

- Companies

- DECHEMA Ausstellungs-GmbH

- Events

- ACHEMA 2022

ACHEMA 2022

ACHEMA - International Exhibition-Congress on Chemical Engineering, Environmental Protection and Biotechnology is held every 3 years (since 1920)in Frankfurt am Main/Germany. Over 4,000 exhibitors and 180,000 visitors from all over the world use this major international event for equipment suppliers of the chemical industry and all branches of the processing industry to exchange ideas and experience and to forge new contacts. The DECHEMA Society for Chemical Engineering and Biotechnology is organizer of this outstanding event.

Modern, interactive and always up to date: With a unique range of topics, exciting focal topics and new event formats, the world`s leading trade show for the process industries brings together experts, decision makers and trendsetters from all over the world.

With manufacturers and service providers from over 50 countries presenting their products for chemical, pharmaceutical and biotech research and manufacturing as well as energy and environmental services ACHEMA is the driving force and groundbreaker for the international process industries and their suppliers.

ACHEMA is home to people with ambitions. ACHEMA attracts 150,000 attendees from 150 countries who make a difference in the process industries and plan to take their business to a new level. There is no other event in the calendar that offers such a comprehensive mix of pioneering technology and global networking - an up-close experience that appeals to all the senses and inspires sustainable connections.

Join the ranks of exhibitors!

ACHEMA is a unique exhibition of the world’s most successful and innovative companies in the process industry. A booth at ACHEMA guarantees interest from a broad, international specialist audience and therefore provides you with the perfect platform to position your brand, generate new leads and meet your existing customers.

Visitors love ACHEMA

- 85% are “satisfied” or “highly satisfied” with their visit to the event, and only 0.1 % are “unsatisfied”!

- 46.5 % of the attendees stay for more than one day (average: 1.9 days).

ACHEMA pools the creativity of the whole sector and showcases the expertise of its exhibitors to a global audience.

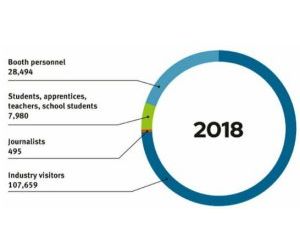

144,628

attendees from 150 countries

3,737

exhibitors from 55 countries

56%

international share

- Engineer: 40.3 %

- Chemist, physicist: 12.7 %

- Foreman, technician, laboratory assistant: 13.6 %

- Commercial professions: 8.6 %

- In training: 12.0 %

- Other jobs: 12.9 %

The Digital Lab

In the lab data from every stage of research and production converge. Modularly designed and fully connected, the digital lab is a data mine for process design and quality control.

Data from all lines of research and production come together in the labaratory. Modular, automated and fully connected, the digital labaratory is a data mine for process development and quality assurance.

Why the focal topic Digital Lab?

Laboratories in industry and research are increasingly becoming habitats for IoT-equipment. Robots that relieve staff from mundane and repetitive tasks such as serial pipetting are state-of-the-art. Yet, smart digital workflows in a fully connected lab are still a long way off most of the time. To achieve them requires at minimum a powerful IT environment and fully integrated equipment; it can also go as far as changing the layout of the lab space. Research labs and quality assurance labs may follow different approaches. Thus a modular setup is as desirable for the lab as it is for production plants. Both lab types are generating a huge amount of data whose analysis calls for a big data approach.

The interfaces between the real and the virtual world demand special attention in times of industry 4.0 and Internet of Things.

Modular and Connected Production

A fully connected value chains makes faster product cycles possible as well as small batches of specialized products.

Smaller batch sizes, faster cycles, connected and modular hardware - digitalization is driving industrial production forward.

Why the focal topic Modular and Connected Production?

Manufacturing processes in the chemical and pharmaceutical industry need to be flexible, fast and cost-efficient. This is best achieved with modular process skids, which can be pre-fabricated and tested in the workshop and then assembled on-site. Skids come with their own programmable logic controller or can be integrated into an overarching process control system. The automation industry is working on an open standard interface; such a module type package (MTP) will allow for true interoperability. Modular plants are the key to meeting the customers’ needs for small batches of varying products. They allow for an effortless adjustment of the plant design to ever- changing requirements and are also the way to change from batch to continuous production.

Why the focal topic Product and Process Security?

Internet of Things (IoT)-devices are increasingly becoming part of operation and production. With every valve that has an IT interface and with every “intelligent” pump sending data into the cloud, IT- and cybersecurity is rising to the top of the list of things to be concerned about. While safety systems are well established and the number of accidents with personal injury is decreasing steadily, cyberattacks are becoming all the more prevalent. Industry 4.0 and the Internet of Things call for an intensified approach to secure the interaction between the physical and the virtual worlds. Identifying, assessing and addressing the vulnerabilities of your business is the first step towards secure products and processes. The whole value chain needs to be covered, too, starting from procurement of raw materials and reaching as far as the recycling of products at the end of their life.

A fully connected value chains makes faster product cycles possible as well as small batches of specialized products.

Smaller batch sizes, faster cycles, connected and modular hardware - digitalization is driving industrial production forward.

Why the focal topic Modular and Connected Production?

Manufacturing processes in the chemical and pharmaceutical industry need to be flexible, fast and cost-efficient. This is best achieved with modular process skids, which can be pre-fabricated and tested in the workshop and then assembled on-site. Skids come with their own programmable logic controller or can be integrated into an overarching process control system. The automation industry is working on an open standard interface; such a module type package (MTP) will allow for true interoperability. Modular plants are the key to meeting the customers’ needs for small batches of varying products. They allow for an effortless adjustment of the plant design to ever- changing requirements and are also the way to change from batch to continuous production.

With over 130,000 m² of exhibition space, ACHEMA is home to the full scope of technology and services for the process industry.

Digital solutions for operations (production and maintenance) & engineering, research & innovation, logistics & supply chain management; software, digital platforms, cloud & infrastructure services, IT Services, IT Consulting, cyber security; augmented reality (AR), virtual reality (VR), artificial intelligence (AI), distributed ledger technology (DLT, blockchain), data virtualization platforms, data models and integration, edge computing, industrial internet of things, big data, machine learning, smart analytics, 5G.

Development, planning and execution of complete production units for all sectors of chemical engineering and biotechnology; catalysts, reactors, microtechnology; CAE - computer-aided engineering; process simulation and software; plants for water and wastewater treatment, waste gas treatment, waste disposal and recycling; services from the areas of logistics, production and financing; supply chain management; chemical parks.

Safety concepts for chemical plants; equipment and measures for the protection of human life and the environment, such as breathing apparatus, oxygen apparatus, protective clothing, monitoring systems, explosion protection, sound insulation, anti-electrostatic techniques, transport of hazardous substances, IT security.

Industrial measurement and control equipment, systems for automatic control and monitoring of operations and processes; data processing systems and programmes for chemical science and engineering, process computers and microprocessors; analytical apparatus for continuous concentration measuring and production control, sensors; electrical engineering systems, equipment and components.

Equipment, facilities, chemicals and services for research and industrial laboratories; laboratory planning and equipment; apparatus for physical and chemical analysis, including sample preparation: weighing and dosing techniques, spectroscopy, chromatography and all related areas, surface analysis, environmental analysis, laboratory diagnostics and laboratory automation; services and contract analysis.

International publishers of scientific and technical literature specialising in: industrial chemistry, process engineering, biotechnology, measurement and control, materials sciences, environmental protection, information systems and databases; manufacturers of learning and teaching aids for universities and vocational training as well as for continuing education at all levels.

Metallic and non-metallic materials and composites for chemical engineering, technical apparatus and equipment made of these materials, surface protection (e.g. enamelling, plating, plasma spraying, coating, refractory linings), welding and joining techniques, microscopy; equipment for physical and chemical testing of materials, materials analysis, metallography, physical surface measurements, diffraction analysis, non-destructive materials testing, component testing, quality assurance techniques during operations, photovoltaic materials and applications.

Plant, apparatus, machines, equipment for mechanical processes, such as mixing, kneading, stirring, screening, filtering (including filter fabrics), centrifuging, crushing, grinding, agglomerating, homogenising, conveying, weighing; drive units and cleaning technology.

Apparatus and machinery for dosing, moulding, filling, sealing, packing, labelling and inspection as well as packaging materials; machinery for the production, manufacture and packaging of drugs; transportation and storage techniques.

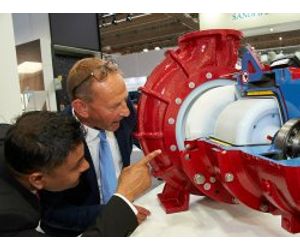

Pumps and compressors for all media, for different operating conditions and loads; valves, fittings, pipelines, seals and packings; high-pressure cleaning equipment.

Areas of work, study courses and research results of university institutes and research establishments in Germany and abroad, relating predominantly to the scientific fundamentals of chemical engineering: industrial chemistry, process engineering, measurement and control, mechanical and plant engineering, materials sciences, environmental protection, biotechnology.

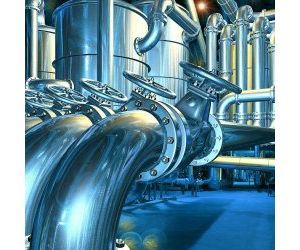

Plant, apparatus, machines, equipment for thermal processes, such as distilling, rectifying, extracting, absorbing, crystallising, drying, heating and cooling; electrochemistry, membrane processes, bioreactors, biorefineries, synthetic fibre processes, power generation, heat pumps, heat transfer and insulation techniques; clean-room technology, air-conditioning, industrial gases; innovative energy sources and -storage, new battery concepts, progress in fuel cell technology.

Chemical and biochemical Reaction Technology

Chemical and biochemical conversion is the basic technology which defines the process industries. New technologies influence equipment and plant design as well as material and product sustainability requirements. Progress in catalyst development, electrification of reactions and integrated (“hybrid”) process steps define all further engineering and design activities. The ongoing pursuit of better energy and resource efficiency and reduction of the environmental footprint has forced the pace of new process development. Innovative techniques such as high-throughput production and micro processes are vital to this research. Integration of chemical and biotechnology process steps combining the best of both worlds is currently a major trend.

Chemical Engineering

Did you know that ACHEMA is the world’s largest show for pumps, compressors and valves? If you think about it, that doesn’t really come as a surprise, as chemical engineering is at the very core of ACHEMA. However, chemical engineering today means much more than simply choosing the right reactor or the most efficient pump. Energy efficiency, the flexibility to choose from a range of possible raw materials and process automation require an integrated approach to process engineering. Components have onboard “distributed intelligence” which enables them to communicate directly – an important prerequisite for modularization and increased flexibility. Heat exchangers and control technologies provide the basis for heat recovery and early separation of waste water streams for further treatment. Simulation and modeling tools support engineering design and planning activities, reduce cost and speed up implementation.

Mixing and Separation Technologies

Mixing and separation technologies are crucial for chemical processes and have a significant impact on efficiency and cost. Further progress in separation techniques employing adsorption methods, membranes or extraction is essential for the success of new processes. Transformation and downstream processing are becoming more integrated, resulting in hybrid methods such as reactive distillation. Another important development is the use of multiphase reactions. Bubble columns play an important role in chemical processing, especially in fermentation and cultivation of microalgae. Efficient mixers are needed for fluid-fluid as well as fluid-solid or fluid-gas systems.

Pharmaceutical Technology

The pharmaceutical industry has very specific requirements relating to process and product quality, starting with the equipment and continuing right through to packaging and labeling. The “Pharmaceutical technology, packaging and storage” exhibition group is growing steadily, and additional exhibition space has been provided to accommodate the applications of producers and service providers. The Congress reflects the importance and specific challenges of this industry in sessions on sterile manufacturing and formulation technology as well as on safety regulations for pharmaceuticals and labeling and tracking technology.

Laboratory Technology

The laboratory world has changed dramatically in recent years. Where formerly a large amount of manual work was necessary to generate data, modern lab equipment today enables researchers to perform literally millions of reactions and analyses in a short time frame. The challenge lies in the ability to handle the tremendous amount of data generated by high-throughput experiments or automated formulation. Sophisticated IT is needed to produce meaningful insights. The IT systems need to be integrated with the equipment as well as with other systems. At ACHEMA, laboratory suppliers shine the spotlight on everything from basic lab equipment to automated modular systems and the software and modeling tools needed to interpret “big data”. The Congress addresses these issues along with laboratory layout and safety.

Materials and Material Processing

Materials and material processing are key success factors in the process industry. The interaction between reaction media, reactants and material surfaces and the correct dosage of ingredients along with product functionality strongly depend on the correct choice of materials and how they are employed. At ACHEMA, the range of materials covered in the exhibition and congress include metals, alloys and all types of polymers. The preparation and application of nanomaterials, foams and powders are discussed. Materials and surface analysis is another important technology which is relevant both for the choice of materials and for quality control during the process. Surface treatment to prevent corrosion makes it possible to combine the “best of two worlds”. Light-weight metals and alloys that are modified to withstand harsh reaction conditions are two examples.

Energy and alternative Feedstocks

Energy, water and feedstock are essential for any chemical or biotechnology conversion. As some of these resources are becoming scarce, new methods for efficient use are being introduced. This includes energy efficient transformations and operations as well as the temporary storage of energy in the form of electricity or heat. Renewable energy resources that produce electricity depending on weather conditions rather than in response to demand may create a temporary and regional surplus of energy. This can be usefully employed for the production of basic chemicals as well as for conversion of unconventional feedstock such as CO2. With the availability of shale gas in the US, coal in China and biomass in Southeast Asia and South America, the choice of feedstock has become much broader and may vary according to region and over time.

Labour and Process Safety at ACHEMA

Safety concepts for chemical plants; equipment and measures for the protection of human life and the environment, such as breathing apparatus, oxygen apparatus, protective clothing, monitoring systems, explosion protection, sound insulation, anti-electrostatic techniques, transport of hazardous substances; IT security.

The exhibition group `Industrial and Labour Safety’ rounds off the exhibition range for visitors interested in safety topics: In Hall 9.1 numerous companies – among them the most prominent companies of the industry – presented their innovations, equipment and technology trends for the protection of man and environment.

Your Company at ACHEMA

Perfect platform

Seize the chance to strengthen your market position. Meet your customers of today and tomorrow at the world`s leading trade fair for the process industry.

Why you should not miss ACHEMA

ACHEMA has been setting standards for over 100 years and brings together experts, qualified users and decision makers from over 145 countries. Become part of the innovation and technology summit of the process industry and present your products, processes and services at ACHEMA.

ACHEMA is home to the full scope of technology and services for the process industry. Manufacturers, service providers and forward thinkers meet at ACHEMA in a single place, thus overcoming the boundaries between different specialist fields and industries.