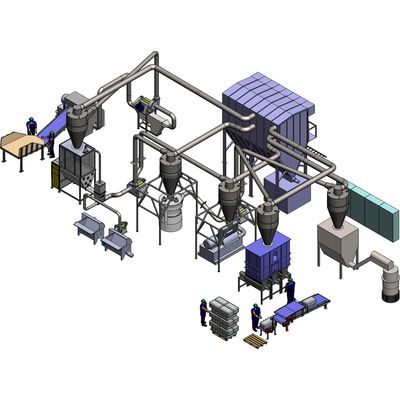

Makron Fibretec - Model Asphalt Additive Production Line -Asphalt Additives from Recycled Cellulose Fiber

Makron Fibretec lines are designed to manufacture fiber additives for asphalt from recycled cardboard or paper. Our production lines come with all the essential features, including equipment to remove dust and impurities. All stages of production can be covered with one complete line. The machines are designed to function perfectly together.

1. Raw-material feeding

The Makron pre-handling table is designed for manual sorting of loose paper or cardboard. For larger capacities, Makron delivers automated feeding systems for cardboard or paper bales.

2. Material Crushing

The raw material is conveyed to the hammer mill or shredder where it is crushed into small pieces for refining. This stage includes a fiber surge bin for intermediate storage. From here the paper pieces are sorted for further processing.

3. Waste Separation

After crushing, the material is moved to waste separation where all remaining metal and heavy particles are separated.

4. Dust Filtering

Dust filters remove all the dust from the process. Air and dust is extracted at all stages of the process through the filters.

5. Refining

The raw material is refined into fibers by the refiner and then stored in the fiber surge bin.

6. Material Conveying

Our complete production lines include belt conveyors for paper raw material. After pre-crushing, the material is conveyed by pipe. Our pipelines also include blowers and cyclones.

7. Granulating

The fiber material can be mixed, for example with bitumen, and granulated. This is an optional stage in the process.

8. Packing

The finished material, recycled cellulose fiber additive for asphalt, can be packed using different packaging technologies depending on your production capacity and needs. Makron’s packaging process packs the fiber into paper or plastic bags, and presses all the air out to make the package compact and ready to transport.

Effective capacity:

1 500 kg/h (cellulose-insulation) and 1 000 kg/h (asphalt fiber)

Required space:

~450 m² + ~300 m² for storing the raw material and final product

Free height of the hall:

At least 7 000 mm

Power supply:

Voltage: ~544 kW+115 kW (granulation equipment)

400/230 V, 50 Hz

Compressed air supply:

Flow rate ~600 l/min, pressure 0,6–0,7 MPa

Water supply:

Pressure 0,2–0,6 MPa only with extinguishing system (option)

Operators:

4–5 persons per shift

Auxiliary equipment:

1 forklift truck, 1–2 hand pallet trucks