- Home

- Companies

- steripac GmbH

- Products

- steripac - Model 3dpac - Blister System ...

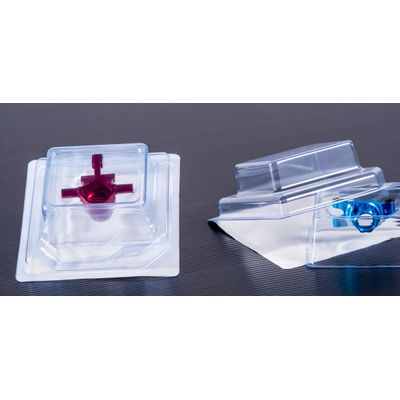

steripac - Model 3dpac - Blister System Transforms Sterile Packaging

For the first time, medical devices are firmly fixed and gently embedded in blister packs. Even the most delicate of products have no room for movement and remain protected from interior abrasion. The thermal process ensures that every fixing inlay is individually moulded to the product. Large product families with a wide range of variants and small batches are optimally and cost-effectively fixed in place. Everything from prototypes to small batches and even individual pieces can be packaged with a standard blister system. There is no need to develop new packaging if product groups are expanded.

3dpac Sterile Packaging is a newly developed blister system from steripac for optimum positional fixing within the sterile barrier.

3dpac comprises three components:

- outer sterile barrier (secondary blister pack)

- inner sterile barrier (primary blister pack)

- fixing inlay

Your medical device lies in the centre of the 3dpac. It is embedded inside the primary blister pack in an individually thermally moulded fixing inlay so that it remains stable when stored. The fixing inlay is thermally produced during the packaging process. The moulding for this is the product that is already in the blister pack. For this reason, the inlay always wraps as soft as velvet around the product, like a second skin, offering uncompromising security.

Each individual packaging process can thereby handle products of different geometries and sizes. The fixing inlays are always separately and individually thermally tailored to the respective product.

When removing the product, the end user first takes the fixing inlay out of the package. The actual medical device remains intact yet easily accessible in the primary blister.

For all highly sensitive medical devices! The fixing inlay provides the product with a custom-made wrapping, allowing it to be stored in the blister pack without risk of movement or abrasion.

The particular strength of the innovative blister design is its adaptability in the case of products with a large number of variants in size and geometry as well as relatively small batch sizes.

Examples of products with a large number of variants:

- Generatively manufactured implants

- Vertebral implants

- Screws

- Plates