LAND® - Model SPOT+ AL -Fixed Spot Non-Contact Thermometer / Pyrometer

A highly accurate and stable digital pyrometer, SPOT+ AL uses LAND’s cutting-edge SPOT technology and unique, advanced data-processing algorithms to measure aluminium temperature in extrusion (E), quench (Q), strip (S), forming/forging (F), forming/forging of higher magnesium alloys (F Mg) and liquid (L) applications.

Most popular related searches:

non-contact thermometer, infrared temperature monitoring, temperature monitoring pyrometer, thermometer, remote sensing, power generation, non-contact temperature monitoring, industrial power, temperature measurement, thermal, infrared, aluminium.

A Highly Accurate and Stable Digital Pyrometer

A highly accurate and stable digital pyrometer, SPOT+ AL uses LAND’s cutting-edge SPOT technology and unique, advanced data-processing algorithms to measure aluminium temperature in extrusion (E), quench (Q), strip (S), forming/forging (F), forming/forging of higher magnesium alloys (F Mg) and liquid (L) applications.

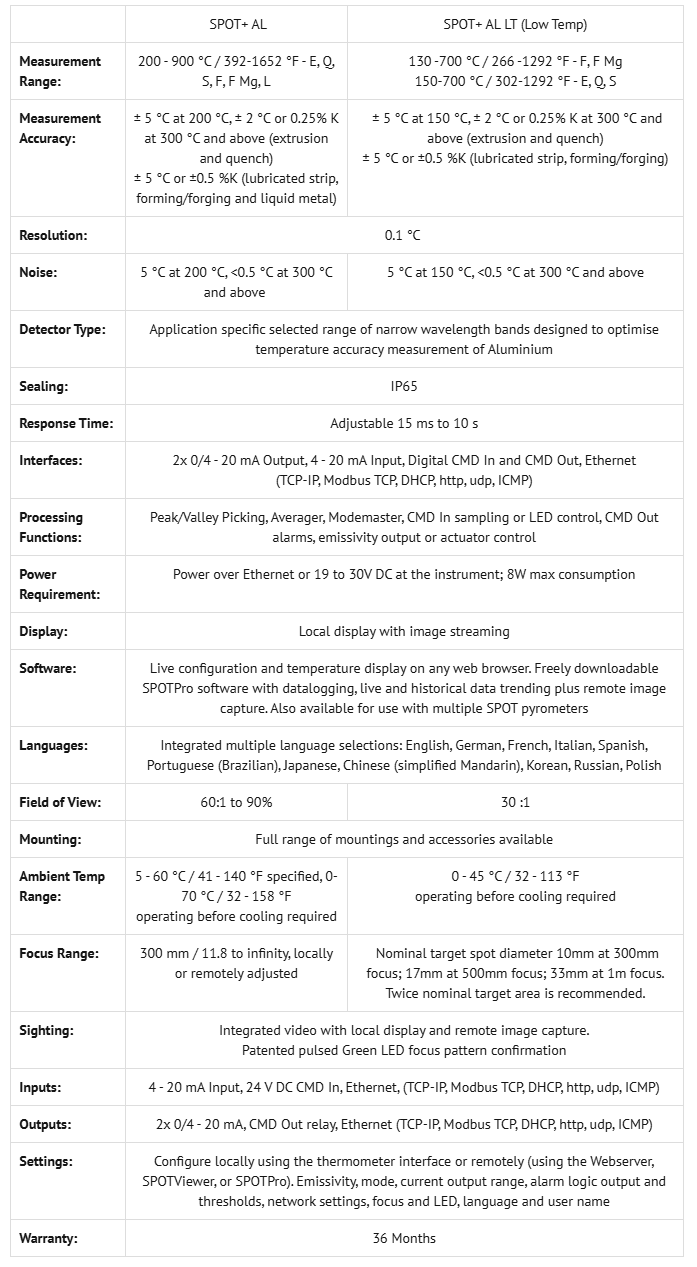

Two versions of the SPOT+ AL are available, the SPOT+ AL version offers a measurement range of 200 °C (392 °F) to 900 °C (1652 °F) and offers six measurement modes (E, Q, S, F, F Mg and L). The SPOT+ AL LT (Low Temp) - 150-700 °C / 302-1292 °F for modes E, Q and S, and 130-700 °C / 266-1292 °F for F and F Mg.

The dedicated pre-set algorithms provide the most accurate digital temperature readings of low and variable emissivity aluminium. This ensures optimised press speed and high-quality products with minimal scrap.

The SPOT+ AL integrates easily with control systems to enable optimisation of the press or mill with data also made immediately available via the rear display on the instrument or via a web server. A video camera within the pyrometer, the focus distance and other features can be accessed and configured locally or remotely.

Combining Ethernet, Modbus TCP, video, analogue, and alarm outputs in a single device, the SPOT+ AL is designed specifically to measure the temperature of aluminium in a range of processing applications.

CUSTOM-APPLICATION MEASUREMENTS

The dedicated algorithms were developed from extensive trials in real plant environments. Fully focusable high-quality optics and a high speed 15ms response combine to provide measurements on detailed extruded profiles.

POWERFUL SOFTWARE SUPPORT

SPOTPro software provides a single control point to configure, store and view data for multiple SPOT+ pyrometers and SPOT Actuators. Giving a complete overview of all devices on your network, SPOTPro allows you to independently configure data logging at response times down to 1ms for each pyrometer and set automatic triggers for data storage. Live and historical data analysis assist you to trend and diagnose process issues.

IMAGEPro software provides a single control point to configure, store and view data and images from multiple SPOT+ thermometers, or a combination of SPOT+ thermometers and thermal imagers. Each device can be independently controlled and data logging configured with automatic triggers for image and temperature data storage. IMAGEPro advanced software functionality allows SPOT+ measurements to be used for live background temperature, emissivity or dirty-window compensation of combined thermal imaging systems, as well as for single-point temperature measurements with a visible light process view.

Learn about next-generation pyrometry for Aluminium temperature measurements for Extruders and Hot Rolling Mills. Advances in features and operational performance help the production of higher specification products for the ever-demanding aluminium market.

- Billet

- Extrusion

- Quench

- Reheat / Slab Haet

- Rolling mill

- Preheating and Forging

- Liquid Aluminium Processing

- Induction Heating

- Mounting / Shrinking

- Preheating for Bending

- Preheating for Coating