- Home

- Companies

- Bio Molecular Systems

- Products

- BMS - Model Myra - Liquid Handling ...

BMS - Model Myra - Liquid Handling System

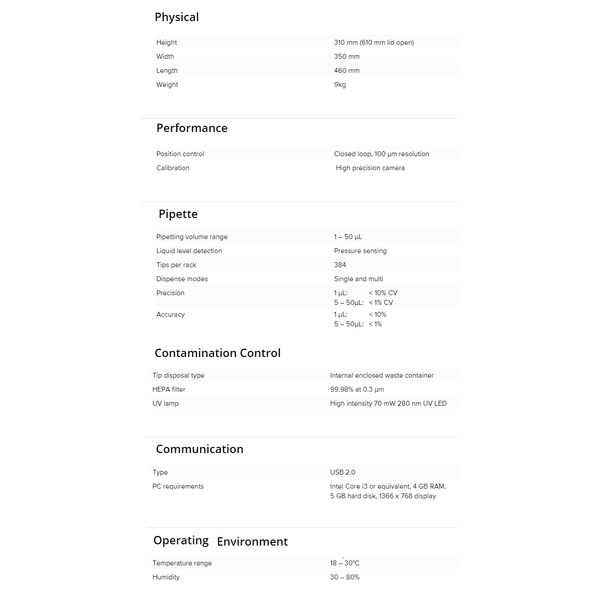

The world’s first liquid handling system that can see. Myra boasts state of the art algorithms and an integrated camera to ensure ultimate precision in your sampling. Save time with Myra’s speed, accuracy and user intuitive software.

Perfect performance for a precise job

The key to excellent data starts with accuracy and precision. With our state of the art pipetting head offering < 1% at 5 uL volumes, Myra will ensure you have confidence in your results.

Save time on the tedious tasks

Reclaim your time with other important jobs. Myra is so precise and speedy, you’ll never have to worry about inaccuracies.

Easy Setup

Myra is the first liquid handling system with an integrated camera to help simplify robot calibration and setup. With an easy user interface that can integrate seamlessly with the Mic. Just setup, run, and analyse all in one location.

Smaller size means more space in the lab

At less that 10kg and a footprint of less than 2ft2, Myra is half the size of other liquid handling systems in her class.

Enjoy a perfectly seamless workflow between the Myra liquid handling system and Mic cycler for qPCR.

Run Myra and Mic instruments from the one user interface. No exporting or importing of sample names required. Just setup, run, and analyse all in one location.

Simplified solutions for standard laboratory processes including qPCR, NGS library quantification*, and more*, all available at the click of a button. Setup experiments for multiple Mic cyclers using one Myra liquid handling system and analyse together in one file using the Project software feature. Calibrate Myra at the click of a button. No more sticking your head under the hood and eye balling the positions. Myra does it all for you.

Myra is a robot built to perfection.

She is the first liquid handling system with an integrated camera and state of the art algorithms. This enables her to see what she needs to do. Myra automates and simplifies pipette calibration and monitors for user errors in deck layout such as missing tubes*.

Her pressure based liquid level sensing can monitor the aspirate and dispense process for errors.

She has best in class accuracy and precision of less than 2% for 2 uL pipetting volumes. Also, a high precision pipette tip positioning for small aperture tubes such as 384 well plates. Using 384 well pipette tips means you swap out tips less often. Additionally, her Multi-dispense pipetting gives greater accuracy to reduce time and save on pipette tips.

An interchangeable pipette head gives you more flexibility with your workflow. Each pipette head contains its own calibration data removing the need to re-calibrate on each exchange.

Myra is a dynamic design with style and function. At less than 10kg and a footprint of less than 2ft2, she is half the size of other in class liquid handling systems.

A closed pipette tip waste container minimises the footprint area and reduces contamination risk.

UV LED lights and a compact HEPA filter reduce the chances of qPCR contamination. The compact design of both parts reduces size and weight of the Myra unit.