- Home

- Companies

- American Cleanroom Systems

- Products

- American-Cleanroom - Medical Device ...

American-Cleanroom - Medical Device Cleanrooms

American Cleanroom Systems® is an expert on medical device, pharmaceutical, nutraceuticals and medical supplier cleanrooms.

Past industry clients have included:

- Allergan

- Baxter

- DuPont

- Johnson & Johnson

- Calhoun Vision

- Medtronic

- Siemens Medical

- Applied Medical

- Burpee Medsystems

- Confluent Medical

- Meditech

- Paragon Vision

- Parker Laboratories

- Tenex Health

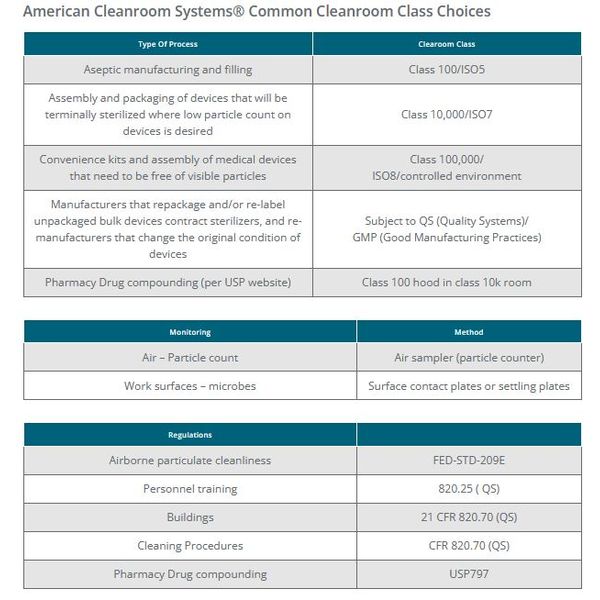

ACS cleanroom options for medical device cleanrooms:

- FRP modular panels for chemical resistance

- Anodized aluminum frame components including internal electrical raceway

- Proprietary ACS coved corner

- Proprietary ACS coved window frame

- Heat welded vinyl floor with integral cove

- Room side replaceable HEPA fan filter units

- Material pass thru’s

- Cart cart pass thru’s

- Door interlock systems

- Temperature and humidity AC systems

American Cleanroom Systems® has a track record of delivering clean room solutions for a large number of world-class medical related companies. We deliver on time and on budget at very competitive prices. Contact us today and we’ll discuss your requirements and submit a project quote within 48 hours.

- proper attire and dressing anteroom;

- controlled use of, and entry into, controlled areas;

- prohibiting eating, drinking, smoking, or gum chewing;

- preventing use of lead pencils;

- regulating the storage of glassware and containers;

- preventing or controlling the cutting, tearing or storage of cardboard, debris, etc.;

- cleaning the room and production equipment per written procedure;

- the original design and cleaning of work surfaces and chairs;

- selecting correct furniture and eliminating all nonessential equipment;

- controlling room air quality (amount of particulates, pressure, velocity, and exchange rate);

- eliminating electrostatic charges by controlling work surface composition or grounding;

- ensuring cleanliness of raw materials, components and tools;

- controlling the purity, sterility, and nonpyrogenicity of process water; and

- maintaining prefilters, HEPA filters, and electrostatic precipitators.

American Cleanroom Systems® modular clean room walls made of FRP (reinforced plastic) and HPL (high pressure laminate) are often used in pharmaceutical, USP 797 compounding rooms, and medical device clean rooms. They can be wiped down with antiseptic. This wall system is an economical and cost effective method to achieve the FDA GMP 9 (QS) and USP 797.

American Cleanroom Systems® also offers standard built seamless epoxy coated cleanroom walls with coved flooring to handle more robust mop down wall cleaning/disinfectant procedures.