VERTISA Medical Waste Technology

- Home

- Companies

- VERTISA Medical Waste Technology

- Products

- Promed - Model A300 - Medical Waste ...

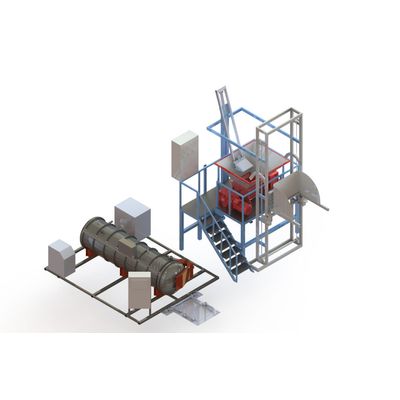

Promed - Model A300 -Medical Waste Sterilization System

The Promed A300 is an advanced medical waste sterilization system designed for medium to large hospitals. Its operation involves a sequence of stages, starting with a loading process where waste is introduced into a chamber. This is followed by shredding, where a PLC-controlled shredder with anti-blocking capabilities grinds even hard materials like surgical stainless steel. During shredding, optional microwave treatment with six integrated magnetron units can be applied. The sterilization is achieved by saturating steam to maintain temperatures between 134°C to 138°C, significantly reducing pathogenic contamination. After sterilization, excess steam is expelled, and the temperature of waste is decreased with cold air. Sterile condensed water is safely drained. This system is certified by TUV Austria and conforms to EU Directives, offering reliability and efficiency for handling medical waste.Most popular related searches

medical waste sterilization system

medical waste sterilizer

medical waste sterilization

medical sterilization system

medical sterilization

autoclave cart

surgical stainless

medical system

surgical

surgical material

Technical Features: Value

Size (L x W x H) (mm): 3000 x 2000 x 2000

Weight (Kg): 2800

Air Pressure (Bar max): 8

Electrical connection required (Kw): 19*

Working Characteristics: Value

Sterilizing Capacity (Kg/ Hour): 300

Process Volume Capacity (Lt.): 2000**

Average Waste Density (Kg/m3): 100 – 150

Average Cycle Time (Min.): 40

Maximum Steam Flow (Kg/Hour): 380

Sterilization Efficiency (SAL): 8 Log10

Consumption / Cycle: Value

Steam (Kg): 32

Electricity (Kw): 7**

Water (Lt): None***

Special Consumables: None

* P50 – P100 – P150 includes built in electrical steam boiler

** Electrical consumption of the sterilizer only

*** Water consumption of integrated steam boiler: 7 – 12 Lt./ Cycle

All Systems can be customized to customer specification