- Home

- Companies

- 3D Systems

- Products

- Model DMP Flex 350 and DMP Flex 350 ...

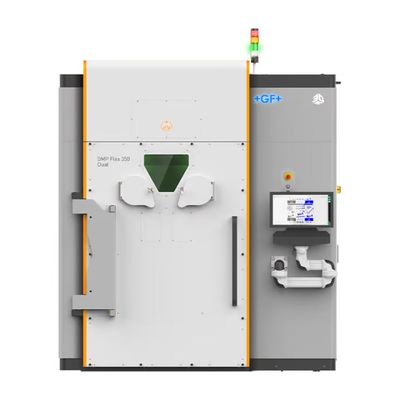

Model DMP Flex 350 and DMP Flex 350 Dual - Metal Printers

Due to the unique vacuum chamber concept of the DMP Flex 350 and DMP Flex 350 Dual, argon gas consumption is heavily reduced while at the same time showing best in class oxygen purity (<25 ppm). This results in exceptionally strong parts of high chemical purity.

With our advanced manufacturing centers, DMP Flex 350 and DMP Flex 350 Dual have been developed from and are continuously improved through closed-loop feedback between the production team and product development. 3D Systems offers you an integrated solution. Our DMP Flex 350 printers with patented technology, the extensively tested suite of advanced materials, 3DXpert metal additive manufacturing software, and finally yet importantly, the expertise of our application engineers to realize time, cost and functionality benefits for our customers. Our users count on reliable material databases for precision metal 3D printing without having to go through the challenging time and cost-consuming effort of developing process parameters themselves.

The DMP Flex 350 and DMP Flex 350 Dual are high throughput, high repeatability metal 3D printers that generate high quality parts in a broad range of alloys. These solutions integrate the printer, software, and advanced materials with expert application support.

Whether you choose the single-laser or dual-laser configuration, the high-performance metal additive manufacturing system is a heavy-duty alternative to traditional metal manufacturing processes: With a build volume of 275 x 275 x 420 mm (10.82 x 10.82 x 16.54 in) it offers reduced waste, greater speeds for production, short set up times and very dense metal parts with excellent mechanical properties.

Application

- Reduced weight/light-weight design

- Orthopedic and spinal implants

Tech Specs

- Uses Direct Metal Printing (DMP) technology

- Build volume (W x D x H): 275 x 275 x 420 mm(10.82 x 10.82 x 16.54 in) –height inclusive of build plate

- Unique vacuum chamber concept

- Best in class oxygen purity (consistently below 25 ppm)

- Quick-swap build modules

- Fast bi-directional powder deposition

- Optional Build Volume Reducer for experimentation with small metal quantities

Benefits

- Simplified assemblies

- Reduced number of parts

- Conformal cooling

- Enhanced fluid flow

- Conformal latticework

- Topology optimization

- Mass customization