Pl Tubing

Polyimide (PI) is a class of functional polymers with outstanding integrated performance. For example, it typically shows remarkable thermal and chemical stability, with a service temperature ranging from -260°C to 400°C, as well as excellent mechanical performance for its superior tensile and compressive strength, high modulus and toughness. Due to an exceptional combination of corrosion and radiation resistance, it can withstand various ways of sterilization; it enjoys low dielectric constant and dissipation; it has the inherent self-extinguishable property that smothers the flame. Thanks to good biocompatibility, micro-sized polyimide medical tubes have been used in catheter interventional medical devices for more than 30 years. Superior tensile strength and burst resistance makethem an appropriate choice for endovascular treatment.

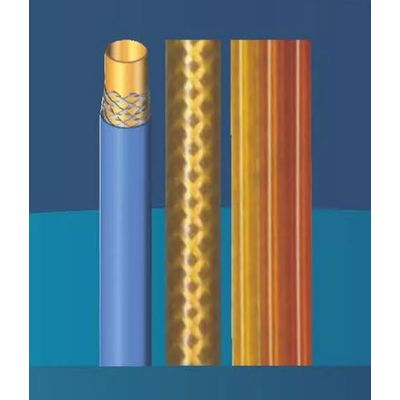

1 Polyimide(PI) tubing

Combing its film-forming properties with Dip Coating technology, different sizes of PI tubes can be designed.

2 PI/PTFE composite tubing

PI/PTFE composite tubing can be customi2ed with their inner and outer surfaces coated with PTFE or PTFE com posite materia Is to red uce the coefficient of friction, provide a low-friction surface, facilitate the push movement of operating parts, and maintain material bonding performance without etching.

3 Black reinforced PI tubing

Black reinforced PI tubing has additional structural reinforced materials to improve its comprehensive mechanical properties with both strength and toughness, and at the same time, the materials also have lubricating and antistatic properties, which help push and prevent static electricity when operating.

4 Braiding reinforced PI tubing

Braiding reinforced PI tubing has a braided reinforced layer, which is made of metallic or non-metallic material and round, flat, multi-stranded in shape overall performance, flexibility and torsion can be controlled through changingthebraidingstructure and density.