Sunkaier

Most popular related searches

active pharmaceutical ingredient

pharmaceutical formulation

drug formulation

pharmaceutical ingredient

pharmaceutical industry

pharmaceutical drug

drug industry

pharmaceutical product

pharmaceutical production

pharmaceutical application

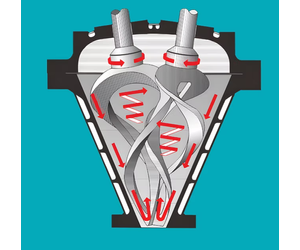

Dual Helical-Conical Blades:

- The mixer features two intermeshing helical-conical blades that rotate within a jacketed conical vessel.

- The blades rotate around their own axis while simultaneously orbiting the central axis of the mixer, creating a planetary motion.

- This dual motion ensures that the material is continuously folded, stretched, and kneaded, promoting homogeneous mixing.

Low-Speed, Medium-Shear Mixing:

- The mixer operates at low speeds, making it ideal for high-viscosity materials that require gentle yet thorough mixing.

- The medium-shear action helps break down agglomerates and ensures uniform distribution of components without damaging sensitive materials.

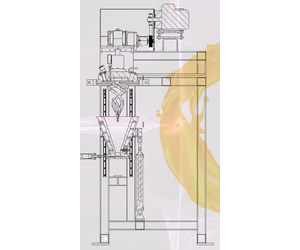

MAIN DESIGN FEATURES

- Full Vacuum, Pressure, and Temperature Control: The reactor provides comprehensive control over process conditions, ensuring optimal results for demanding chemical reactions.

- Variable Blade Speed: Adjustable mixing speeds allow for tailored processing, accommodating a wide range of viscosities and reaction requirements.

- Versatile Applications: Ideal for polymerization, condensation reactions, and other complex processes in industries such as pharmaceuticals, plastics, polymers, and chemicals.

- Scalable Batch Sizes: Available in various models to accommodate batch sizes ranging from 5 to 200 litres, offering flexibility for both small-scale and industrial applications.

- ASME Certified: The reactor bodies are ASME certified, ensuring compliance with rigorous safety and quality standards.

- Efficient Mixing: The dual helical-conical blades ensure uniform mixing, even for highly viscous materials.

- Process Control: Full control over vacuum, pressure, temperature, and blade speed allows for precise optimization of reaction conditions.

- Safety and Reliability: ASME certification ensures the reactor meets high safety standards, making it a dependable choice for industrial applications.

- The CKD reactor is a robust and versatile solution for industries requiring advanced mixing and reaction capabilities, particularly for high-viscosity materials. Its combination of innovative design, precise control, and scalability makes it an essential tool for modern industrial processes.

Pharmaceutical Industry

- Drug Formulation: Ideal for mixing and homogenizing high-viscosity pharmaceutical formulations, such as ointments, creams, gels, and pastes.

- Active Pharmaceutical Ingredient (API) Production: Ensures uniform dispersion of APIs in excipients.

- Devolatilization: Removes solvents and volatile impurities under vacuum, ensuring high-purity final products.

Polymer and Plastic Industry

- Polymerization: Efficiently handles polymerization reactions, including bulk, solution, and condensation polymerization.

- Compounding: Mixes polymers with additives, fillers, and reinforcements to create composite materials.

- Masterbatch Production: Ensures uniform dispersion of pigments and additives in polymer matrices.

- Thermoset Processing: Mixes and processes thermosetting resins, such as epoxies and polyurethanes.

Chemical Industry

- Condensation Reactions: Ideal for reactions that release by-products, which can be removed under vacuum.

- Adhesives and Sealants: Homogeneously blends high-viscosity adhesives, sealants, and coatings.

- Resin Production: Mixes and processes synthetic resins, such as phenolic, polyester, and acrylic resins.

- Catalyst Preparation: Ensures uniform dispersion of catalysts in chemical reactions.