Ace Technologies

- Home

- Companies

- Ace Technologies

- Products

- Ace - Rotary Powder Filling Machine for ...

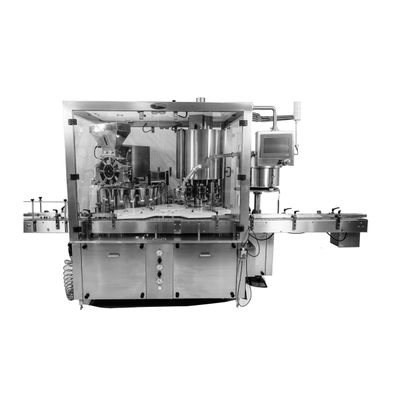

Ace - Rotary Powder Filling Machine for Pharma & Healthcare

FromAce Technologies

The Rotary Powder Filling Machine is designed to handle a wide range of powder filling requirements in the pharmaceutical and healthcare industries. This machine is capable of outputting between 180 and 150 BPM for powders ranging from 3 grams to 50 grams, utilizing a 24x8 rotary head configuration. It features a PLC and HMI system, specifically the Delta HMI make, which allows for precise control and monitoring of the filling process. This equipment is part of the indigenous range, known for its applicability in dry syrup and liquid filling lines, and employs volumetric filling techniques. This machine is particularly suitable for environments where maintaining consistent fill weights and minimizing product waste are critical.Most popular related searches

pharmaceutical healthcare

healthcare industry

healthcare pharmaceutical

pharmaceuticals

pharmaceutical industry

Output : 180 – 150 BPM for 3 grm to 50 Grms with 24X 8 Rotary Head

(Depending upon the powder properties)

- The machine works on Vacuum Based Rotary principal for filling of dry syrup powders for high output.

- All contact parts of SS 316 and non-contact parts of SS304.

- No Bottle – No Fill mechanism – To avoid spillage /wastage of powder in absence of bottle below the filling head.

- Air Filter of SS316 housing with Nylon cartridge for proper removal of particle of 0.22 micron.

- 5 Micron Vacuum filter with nylon cart

- PLC controlled panel with touch screen for precise setting for filling and recipe storage.

PLC & HMI (Make Delta HMI ).

- Polycarbonate covers are provided with SS panel for dust free operations.

- Batch Recording , integration with MES system.

- High productivity with low space consumption due to Rotary principal.

- Weight variation: Less than +/- 2.0% subject to the powder nature, fill weight & speed.

- Ease of maintenance and changeover due to less parts.

- Central Clutch for extra safety.

- No Spillage of powder: Dripping of the powder can be controlled after filling, hence avoiding powder spillage on bottle outer diameter.

- Bottle Jam sensors and powder level sensor provided for ease of operation.

- Long Life- Separate Electrical panel to avoid dusting in the electrical panel.

- Motorized elevating assembly to adjust the height of rotary filling head as per the height of bottle.

- Ac Variable drive to adjust the speed of the machine.

- Low Air Pressure Indication.

- Low Vacuum indication.

- Infeed / Outfeed no Bottle Indication.

- No Bottle No Fill Indication.

- Out Feed Bottle jammed Indication.

- Empty bottle detection and rejection.

- Low Powder level alarm.