Gansons

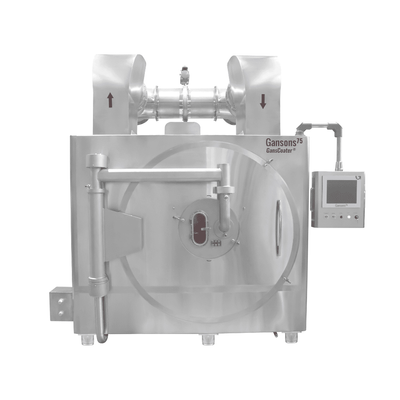

Gansons GansCoater - Tablet Coater for Pharmaceutical Applications

FromGansons

The GansCoater is a highly advanced tablet coater designed for regulated pharmaceutical manufacturing. It integrates the experience of four decades to provide efficient and reliable coating solutions across various types of tablet coatings, including enteric, multi-layer, and sugar coatings. Key features of the GansCoater include proprietary GHPN-IIIRD spray nozzles that reduce air consumption and spray losses, an exceptionally smooth coating pan for defect-free results, and interchangeable pans that reduce downtime. It also boasts intelligent automation with PLC/IPC-SCADA systems for compliance with 21CFR11 and GAMP5 standards. The GansCoater is IoT enabled for enhanced control and monitoring. Its Aeroflo Baffles improve mixing and drying, while infrared sensors ensure precise temperature control. Capable of handling 500 grams to 1,000 kilograms, it features automatic tablet loading and unloading and is compatible with isolators for OEL 4 and 5 products, making it a versatile choice for scalable pharmaceutical operations.Most popular related searches

Proprietary GHPN-IIIRD spray nozzles

- Anti-bearding

- No elastomeric contact parts = easy to maintain + lower risk

- 30% less compressed air consumption*

- Less than 5% spray losses

- Wide spray coverage with uniform droplet size

- *compared to industry standards

Astonishingly Smooth Coating Pan

- Less than 0.1 Ra value for defect-free tablet coating

- High open area for maximal drying efficiency

- Optimized pan geometry for fast and uniform coating

Interchangeable Coating Pans for flexible processing (less than 5 minutes downtime!)

- Flexible processing with large turndown ratio

- Easy 6-minute single operator changeover

Infrared Sensors provide accurate measurement and control over tablet surface temperatures.

- For accurate tablet bed temperature measurement

Gansons Aeroflo Baffles enhance mixing and drying efficiency

- Read more about how Gansons Rabbit Ear baffles offer superior mixing and tablet-turnover as compared to other types of baffles used in coating pans.

Intelligent Automation for reproducible and risk-free processing

- PLC/IPC-SCADA based systems for 21CFR11 compliance (GAMP5)

- Internet of Things (IoT) enabled

- Customizable recipe management

- Multi-level access management

Other features:

- Automatic tablet loading and unloading

- Recipe driven Wash-in-Place (WIP) system

- Isolator compatible for OEL 4 and 5 products

- Watson Marlow peristaltic pumps for precise dosing of coating material