- Home

- Companies

- Nanova Biomaterials, Inc.

- Products

- FiberFix - Technology: Nanofiber ...

FiberFix - Technology: Nanofiber Hydroxyapatite Composite

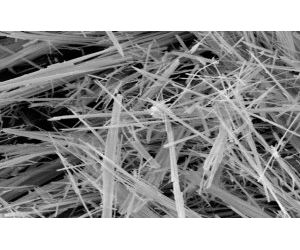

Human bone is made up of plate-like hydroxyapatite (2-4 nanometer thick and up to 100 nanometer long) embedded in a collagen-rich protein matrix. Biocomposites’ containing hydroxyapatite (HA), benefit by improving biocompatibility or osteoconductivity, and reducing self-catalytic degradation. In literature implants with HA have been resorb and replaced by bone1. NBI has developed a method to mass produce single crystalline hydroxyapatite nanofibers with well controlled size and purity. Such HA nanofibers are typically around 100 nanometers in diameter (1000 time thinner than hair) and tens of micrometers in length.

FiberFIXTM represents a new generation of bioresorbable materials developed by our breakthrough nanotechnology. Just like rebar in concrete, our specially modified nanofiber can effectively strengthen the mechanical properties of the composites. Our FiberFIXTM suture anchors and interference screws have demonstrated enhanced resistance to breakage/stripping during insertion and increased pull-out strength after-insertion, which reduces the failure rates during orthopedic operations.

FiberFIX™ provides orthopedic devices with optimized material properties and precision designs. FiberFIX™ implants are made from our patented bioresorbable polymer composite that is reinforced by our customized high-aspect ratio single crystalline hydroxyapatite (HA) nanofibers. Just like rebar in concrete, inclusion of such nanofibers in polymer composites enhances the physical strength of our FiberFIX™ implants and reduces their failure rate during operations. In addition, the desirable chemical property of HA further makes our FiberFIX™ implants less vulnerable for self-catalyzed acidic degradation and related inflammation responses. FiberFIX™ also modifies, improves and fine-tune designs on orthopedic devices to deliver excellent handling and performance to clinicians.

A fiber with a diameter of 100 nm or 1000x smaller than a human hair. NovaFibers™ are made with single crystal hydroxyapatite, similar to bone. The long, thin fibers offer improved tensile strength and greater surface area.

FiberFix™ hybrid nanocomposites with NovaFiber™ technology act similar to concrete reinforced with rebar. Ceramic fiber strength is inversely proportional to the diameter of the fiber. With NovaFiber™, the length of the fibers gives greater load transfer throughout the composite while the thin, single-crystal diameter offers maximum strength.

FiberFix interference screws and anchors combine excellent mechanical design with NovaFiber™ materials technology to exceed the performance of current market offerings.

- Greater max torque

- High pullout force

Nanova Biomaterials Inc internal testing has shown FiberFix™ Interference Screws and Suture Anchors to offer high max torque, pullout force and rope pullout.

Hydroxyapatite nanofiber with over-100 times greater surface area compared to traditional calcium phosphate particles, improve the acid buffering ability of FiberFIX™ devices, reduce acidic degradation of the composites, and minimize the body’s inflammatory response. Real-time degradation tests on our FiberFIX™ devices have also indicated adequate mechanical stability for 3 months and no sign of self-catalytic degradation over 2 years of observation

Current commercial biocomposite implants containing calcium phosphate additives are generally in granule/particle form, these often make the resulting composites weak and brittle. Just like rebar in concrete, our specially modified nanofiber can effectively strengthen the mechanical properties of the composites. This delivers high max torque, and pullout resistance in the FiberFIX™ line of devices.

FiberFix™ hybrid nanocomposites are more ductile allowing them to bend before they break. This gives surgeons a warning so they can prevent insertion breakage.

Other biocomposites reach their point of max torque and snap abruptly1. This can add serious complications, risk, and added time to surgeries.