Saertex GmbH & Co.KG

- Home

- Companies

- Saertex GmbH & Co.KG

- Products

- Saertex - Ultra Fatigue UD for ...

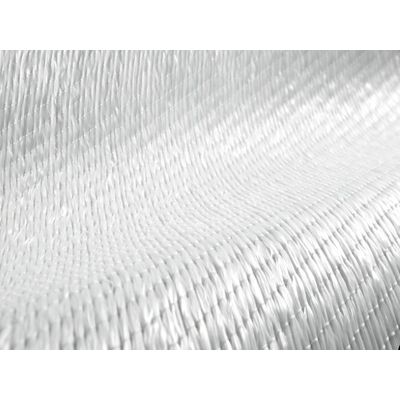

Saertex - Ultra Fatigue UD for Unidirectional Fabric

Unidirectional fabric for components subjected to high dynamic loads. Ultra Fatigue was specifically developed for leaf springs in the passenger car and truck sectors. The unidirectional fabric saves up to 50% in weight compared to steel, boasts a longer service life and features outstanding fatigue properties. Processed using the RTM process, it can be used with epoxy and PU resins and is ideally suited for high volume production.

Most popular related searches

- Achieve your lightweight construction goals

The non-crimp-fabric is up to 50% lighter than steel and therefore offers high potential for lightweight construction. The result is an overall reduction in vehicle mass and an enormous increase in payload. - 12 times longer fatigue life

Ultra Fatigue also has a significantly longer service life compared to steel. This is due in part to the new fatigue properties that the traditional non-crimp-fabrics do not have. A fatigue test was also carried out according to the international standard ISO 13003. - Improved shock absorption

Due to the fatigue properties, the absorption of the strain energy, also compared to steel, was significantly improved. Occurring vibration noises were largely reduced and optimized. - Increased corrosion resistance

Ultra Fatigue UD is resistant to all weather conditions and corrosion. - Material for your application - customizable

The fabric can be even further optimized for infusion behavior. The fibers used can be varied and are therefore very suitable for your specific requests. This means that the weight per unit area can be adjusted from 985g/m² and the fabric is available in different tapes and widths. Another big advantage is that Ultra Fatigue UD can be combined with our other products such as SAERcore and SAERfoam. - Good handling for high product series

The fabric is easy to process using the RTM process and is also easy to use with epoxy and PU resins.