- Home

- Companies

- Advanced Energy Industries, Inc.

- Services

- Implant & RTP Solutions

Implant & RTP Solutions

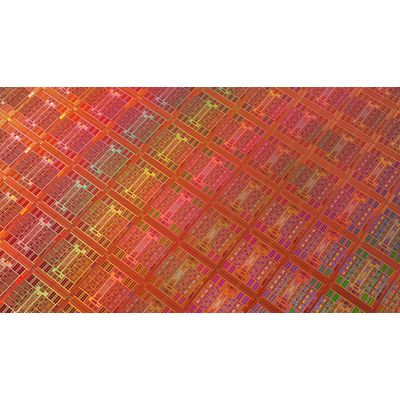

Tailor and optimize your power accuracy, precision, speed, and process repeatability. Overcome your wafer processing challenges. Advanced Energy transforms power delivery and control solutions for ion implantation, rapid thermal processing applications, and device geometries. Utilize our precision power conversion solutions to tailor and optimize your power accuracy, precision, speed, and process repeatability. And our non-contact temperature measuring technologies enable better control of your annealing processes.

As the semiconductor industry drives device feature size toward the nanometer, you look to improve device speed, better low leakage currents, and reduce power consumption. These priorities create unique implantation challenges for front-end processes.

For the four types of ion implantation processes — high-current, medium-current, high-energy, and plasma doping — energy purity, ion-beam-angle control, and uniformity are critical variables. Once the implant is completed, you must thermally condition the wafer (anneal) to activate implanted regions and repair damage to the crystal structure of the wafer surface.

Solve all your implantation process challenges and experience the convenience of working with one dedicated supplier. Advanced Energy offers various high voltage supplies for creation, filtering, and directionality of the ion beam. Collaborate with us to develop your customized implantation solutions and supplies:

- Arc supplies to create the plasma (source of ions)

- Ion extraction supplies

- Ion accelerator supplies

- Quad Lens supplies (focus the ion beam)

- Deceleration supplies (ion-beam-energy control)

- Suppression supplies (eliminate unwanted ions)

- Beam-energy filtering supplies (refine the beam’s energy)

We also offer advanced, non-contact temperature measurement solutions.

- Broadest range of high voltage outputs available for implantation, doping, and annealing applications

- High power density to permit a means a smaller supply for easy tool integration

- Direct Drive Digital Control™ (D3C™) technology and control for improved MTBF and reliability

- Temperature measurement with exceptional stability

- Active emissivity compensation for improved accuracy