- Home

- Companies

- Fette Compacting

- Services

- Lab Solutions for Optimized ...

Lab Solutions for Optimized Pharmaceutical Production

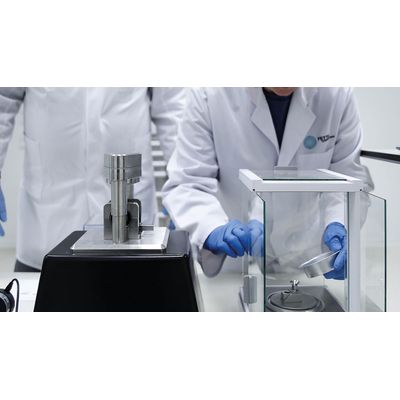

Fette Compacting's Lab Solutions provides an in-depth analysis of your raw materials, production parameters, and product quality through its comprehensive service suite. Utilizing the Quality by Design (QbD) approach, they focus on determining Critical Material Attributes (CMAs) for raw materials, Critical Process Parameters (CPPs) for production, and Critical Quality Attributes (CQAs) for the final product. With extensive experience in pharmaceutical, process, and mechanical engineering industries, their services ensure efficient and high-quality production processes. The laboratory specializes in powder formulation analysis to understand the material attributes that influence flow, compaction, and tableting characteristics. Their analytical services extend to content uniformity, disintegration time, and friability testing, ensuring the safety and efficacy of pharmaceutical tablets.

Lab Solutions is our service providing you with a comprehensive insight into your raw materials, production parameters, and quality characteristics. With this knowledge, we enable you to produce according to the Quality by Design (QbD) approach. Regardless of whether your product is in the development or already in the market phase: We determine Critical Material Attributes (CMAs) of the raw materials, Critical Process Parameters (CPPs) of production and Critical Quality Attributes (CQAs) of the final product through a comprehensive range of analyses. With many years of experience in the pharmaceutical industry, process engineering and mechanical engineering we guide you in designing your production efficiently and to the highest quality using Quality by Design.

The Services at a glance:

- Lab services for material and tablet characterization

- Powder Compaction Analysis

- Data and Know-how driven optimization of R&D and production processes

- Trials including pre-defined as well as customized characterization of materials and tablets according to your needs

In our laboratory, we analyze, characterize and evaluate your powder formulations using a variety of methods. We look at the physical parameters that significantly influence the flow properties, compacting behavior and tableting characteristics of your powder. This enables a comprehensive understanding Critical Material Attributes (CMAs) of your raw materials and their impact on the tableting process and thus on the quality of your product.

By combining the knowledge gained from powder and compacting analyses with tableting tests, we work with you to determine the Critical Process Parameters (CPPs) of your production. This is how we achieve:

- Cost-efficient production through increased output and reduced losses

- Compliance with technical requirements

- Adherence to regulatory standards

Critical Quality Attributes are crucial parameters that manufacturers strictly control and monitor throughout the production process to ensure the quality, safety and efficacy of the final product. Our analytical services also include the determination of content uniformity, disintegration time and friability, which are key aspects of tablet quality.