THY Precision - Medical Injection Molding Company in Taiwan with Cleanroom Injection Molding Manufacturing

Precision injection molding is an advanced and specialized technique that relies on precision injection molds and state-of-the-art machinery. It differs significantly from standard injection molding methods and is crucial for creating precise plastic components with intricate designs.

THY Precision excels in producing precise plastic components through precision injection molding. Our services include the following:

- Micro Molding

- Medical Injection Molding

- Optical polymer molding

- Family Tooling

- Insert Molding

- Cleanroom Injection Molding

- Scientific Molding

- Ultra Precision Molding

- High Temperature Molding

- High and Low Volume Molding

The entire mold design process is meticulously planned and communicated to guarantee that the tooling aligns with the product’s intended specifications, encompassing the selection of machine types and sizes for the production.

At THY Precision, we utilize the newest and most advanced Moldex 3D software to achieve the highest quality and most efficient results. Before manufacturing the mold, engineers use Modex 3D simulation to verify their designs and prevent any potential short shots or tolerance errors. In addition to discovering potential problems in advance, Moldex 3D helps improve and optimize design. This technology prevents any trial-and-error experimental methods and saves customers’ time and money.

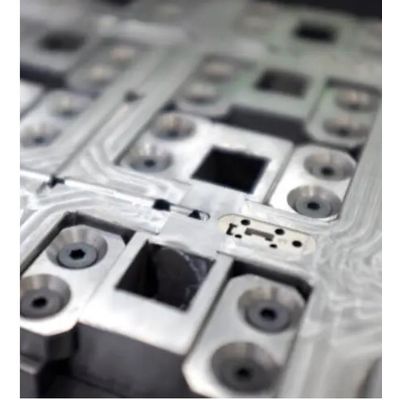

Achieving precision-molded plastic parts with strict tolerances and consistent quality depends on the use of precision injection molds and tooling. The molds play a pivotal role in ensuring that each component meets the exact specifications outlined in the design engineering phase, ensuring accuracy and consistency in every part produced.