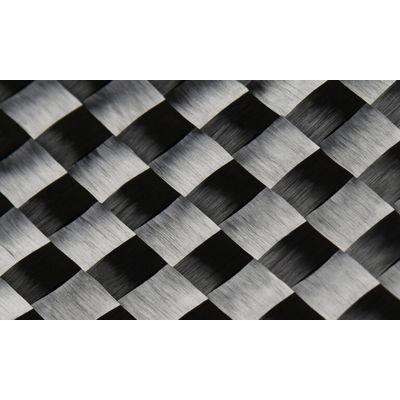

CREAMEDTEC - Composite Materials

Compared to conventional plastics and metallic materials, CREAMEDTEC composite materials are excellently suited for clinical applications. CREAMEDTEC products not only absorb less moisture than conventional plastics, but are also multi-sterilizable (steam, ethylene oxide, gamma radiation). The composite material used exhibits greater strength and significantly lower weight than metallic materials, making it ideal for clinical applications.

- Radiolucent properties provide transparency for X-rays

- High strength and rigidity

- Light weight

- Resistance to repeated sterilization, e.g., autoclave, gamma radiation

- Form stability

- Unique chemical resistance

- Very low water absorption

Creamedtec® 1475

CREAMEDTEC® 1475 is an advanced, continuous carbon fiber/PEEK composite material manufactured by compression molding. Specifically developed for the extreme technical requirements of medical trauma devices, CREAMEDTEC® 1475 is ideally suited as a metal replacement due to its high strength, dimensional stability, low weight, and corrosion resistance.

Creamedtec® UD

CREAMEDTEC® UD is an advanced, modified long-fiber carbon composite manufactured using a compression molding process. Specifically developed for the extreme technical demands of medical traumatology, CREAMEDTEC® UD's high strength and dimensional stability make it ideal for replacing metal where radiolucency and repeated autoclaving are required. CREAMEDTEC® UD is designed to replace complex parts while offering greater design freedom, lower costs, and lower weight.

Creamedtec® 5050

CREAMEDTEC® 5050 is a modified carbon fiber/PEEK composite produced by transfer or injection molding and used for a wide variety of demanding orthopedic instruments. Due to its strength and dimensional stability, CREAMEDTEC® 5050 is ideally suited to replace metal when radiolucency and autoclavability are required. CREAMEDTEC® 5050 was developed for injection-molded thick carbon fiber composite parts with free-form surfaces.

Creamedtec® 134

CREAMEDTEC® 134 is an advanced, long-fiber carbon fiber composite material manufactured using a pultrusion process. Specifically developed for the extreme technical requirements of medical technology, CREAMEDTEC® 134 is ideal as a metal replacement due to its high flexural and torsional stiffness, dimensional stability, low weight, and corrosion resistance. CREAMEDTEC® 134 is recommended for complex parts such as stabilization and fixation devices where radiolucency and high overall strength are required.