- Home

- Companies

- DR SYSTEMS

- Products

- VISIO - System for Automated Weld Joint ...

VISIO - System for Automated Weld Joint Inspection

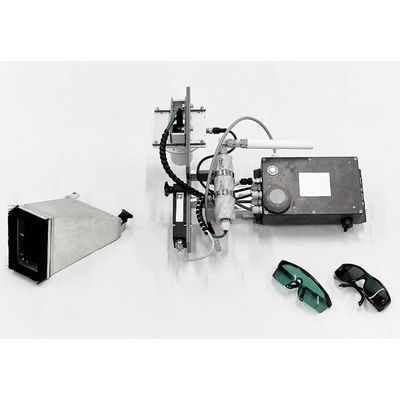

The VISIO System provides automated visual and dimensional inspection of circumferential weld joints in pipes with a diameter of 273 mm (10 inches) or more. Suitable for integration into the XPRESS-SCAN® digital radiography complex or as a standalone unit, the VISIO System captures, processes, and archives digital profiles that reflect the shape and dimensions of weld joints. It employs a laser triangulation 2D scanner mounted on a carriage designed to traverse annular welds on pipe bands per pre-set protocols. Operating either stationary or in motion, the system's carriage moves precisely to cover the entirety of weld joints, sending inspection results wirelessly in real-time to an operator's PC. This technological advancement enhances digital radiography by providing real-time, high-resolution image data, aiding in comprehensive weld analysis and ensuring adherence to quality standards.

VISIO system is designed for automated visual and dimensional inspection of circumferential weld joints of pipes from 273 mm (10 inches) and more. VISIO can be used either as part of the XPRESS-SCAN digital radiography complex or as a standalone device. The main purpose of the system is to acquire, process, and archive digital profiles characterizing the shape and dimensions of weld joints.

The unit consists of a laser triangulation 2D scanner mounted on a carriage, which moves along the annular weld on a pipe band according to a pre-set program. Inspection can be performed both with the module stationary and in motion: the carriage moves from one position to another, covering the entire weld joint. The control results of the weld joint are transmitted to the operator's PC in real-time wirelessly.